Capital - White Paper

Wiring harness assembly - Solutions for vehicle electrical systems

TEL: +44 (0)845 644 0914

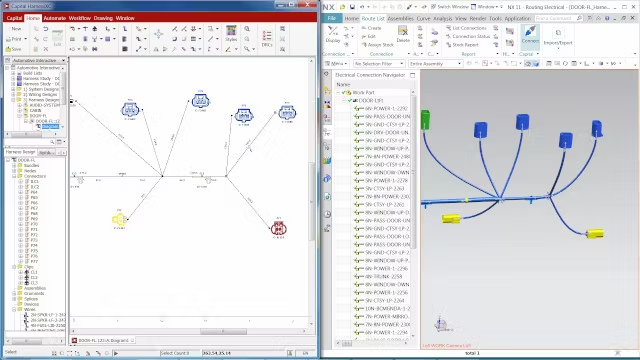

The expansion in size and intricacy of automobile electrical systems is leading to heightened development expenses and a greater probability of errors. Novel electrical systems and wiring harness design solutions are being implemented to automate processes, facilitate joint efforts, and accelerate verification in order to reduce design costs, abbreviate cycles, and diminish the risk of errors associated with the electrical system.

The subsequent whitepaper will provide a thorough overview of the design and appraisal of a wiring harness for a small tractor through the utilization of Capital Essentials: a suite of wiring and harness design software tools tailored to meet the intensive requisites of companies that prioritize both ease-of-use and capability.

Maximize product cost reductions with harness design software

The expansion of electrical networks can increase the expenses of vehicle development twofold, due to the intrinsic costs of additional wiring and components, as well as the time and resources required to formulate a complex system. Additionally, intricate pathways and circuits necessitate multiple revisions and re-designs, further contributing to the already high overheads associated with creating wiring harness assemblies.

Harness design software can leverage automation to decrease design expenses. By leveraging the capabilities offered in these software solutions, automakers can fulfill the needs of product complexity and quality while optimizing product cost cuts.

Verifying vehicle electrical systems

A quantitative analysis of vehicle electrical systems is a critical step to verify circuit logic accuracy and proper connections within the design. The analysis provides real-time intuitive feedback on the basic behavior and connectivity of circuit designs, enabling engineers to quickly identify and correct issues.

Managing wire harness design with Capital Essentials

Capital Essentials offers engineers design and analysis functionality to achieve swift, precise, and mistake-free electrical and harness designs. Our wire harness design utilizes a reliable digital thread that ensures traceability throughout the development process, from requirements to harness manufacturing. Both our design and harness tools can be used independently or together, enabling seamless flow of wiring design data into harness designs, and minimizing effort and risk of errors.

Download the white paper to learn how Capital Essentials helps users achieve dramatic ROI using powerful yet intuitive functionality.

Learn More

CASE STUDY

Global vehicle manufacturer uses Capital software to develop a digital thread across the entire product lifecycle

Siemens EDA solutions enable Navistar to improve creation of customer service documentation and the service technician troubleshooting experience

1

WHITE PAPER

Autonomy, electrification & rise of model-based E/E design

Read this paper to learn about a powerful software that automatically transforms input models into deterministic outputs, transforming automotive electrical and electronics (E/E) design.

WHITE PAPER

Automotive ECAD-MCAD Co-Design for First-Pass Success

For continued success, automotive companies must adopt and ECAD-MCAD co-design solution to give then the best chance at first pass success. Discover what’s possible with directly connected electrical and machanical domains.