Enhancing Power Integrity for Reliable and Efficient Product Design.

Pre- and post-layout analysis of your PCB’s power delivery can lead to a more robust power system, allowing you to get to market faster and have confidence in your PCB design.

Optimizing power delivery with effective decoupling is essential to resolve power-delivery issues. Issues such as the number of decoupling capacitors, which values to use, and how to mount the capacitors need to be addressed, as well as optimizing your design to reduce cost and use fewer layers.

Learn about:

Pre-Layout planning for low impedance

Post-Layout decoupling verification methods.

Optimisation of decoupling devices for cost

LIMITED SPECIAL OFFER

HyperLynx Power Bundle

Optimize your electronic designs with HyperLynx Power Bundle. Predict and solve power distribution issues early, eliminate costly prototype spins, and ensure reliable, high-performance designs.

Get the 6 Month License now!

Overview

Every modern electronic design includes a Power Distribution Network (PDN) with two critical and equally important purposes:-

- Supply stable power to components from DC to ~150 MHz

- Provide controlled return paths for high-speed signals.

When a PDN fails to meet these goals, the design can fail to operate at intended performance levels, or even worse, fail intermittently and unpredictably. Poorly designed PDNs can create current and thermal stresses that exceed physical material limits, causing the PCB or ICs to burn out prematurely.

Hardware engineers, PCB designers, and signal integrity specialists alike can use HyperLynx PI to predict PDN performance quickly, without requiring weeks of training. HyperLynx PI identifies power distribution problems early in the design cycle, even prior to layout. Designers identify problems that would be difficult to isolate in the lab, investigating potential solutions using an interactive “what-if” environment. Once layout is complete, HyperLynx PI completely validates PDN behaviour as part of electrical sign-off. HyperLynx PI lets you eliminate prototype spins and get to market faster, while creating more reliable and cost-effective designs.

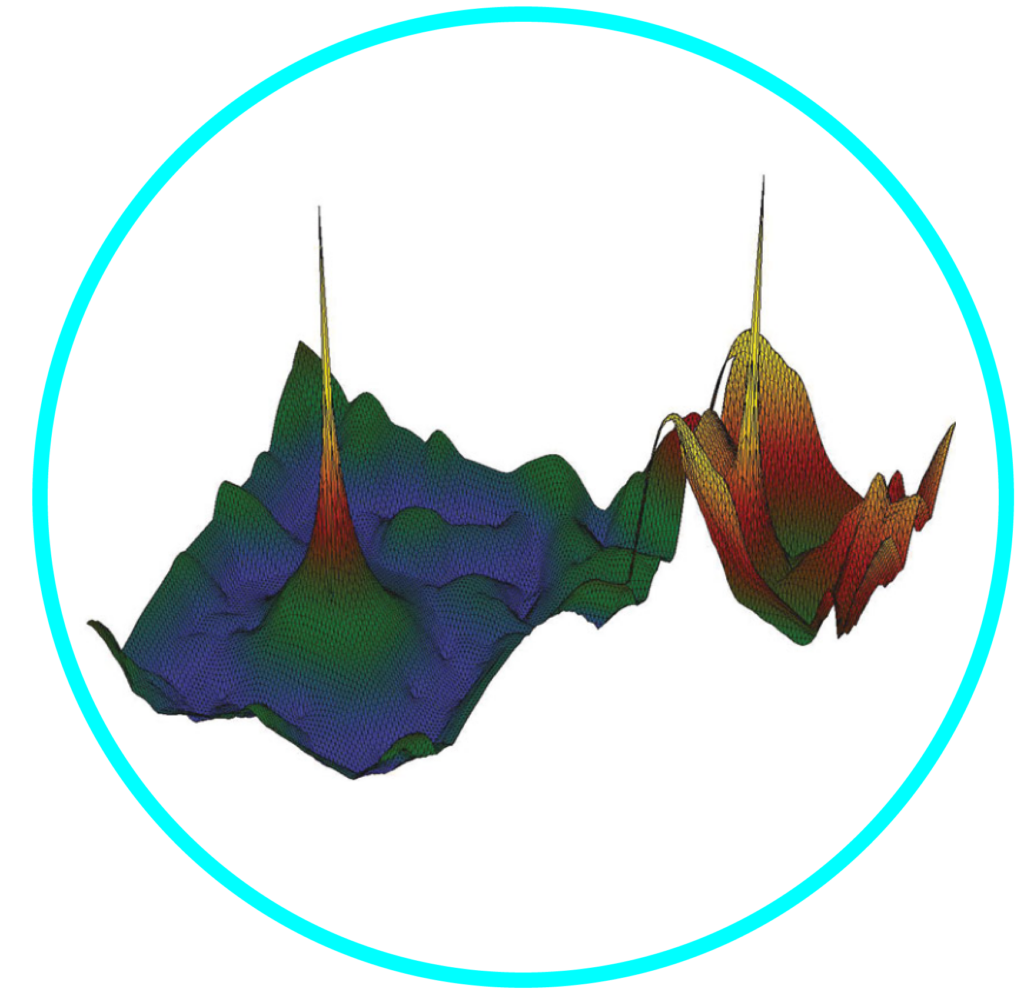

Screen Shots

Power Integrity Features

- Touchstone file viewer/checker/transformer

- 3D power viewer

- Stackup editor / field solver

- DC Drop Analysis – complete modeling and reporting, multiboard support

- DC Drop Analysis – Remote sense line and Multi-phase VRM support

- Thermal / DC drop co-simulation

- Decoupling analysis – complete modeling and reporting

- Decoupling acceleration (multi-core simulation)

- Plane noise analysis

- Dyn. current demand modeling (core, I/O, power up, etc)

Thermal Features

- Enclosure modeling

- 3D component modeling

- Board / layer copper modeling

- Cooling components – heat sink, heat pipe, chassis screw