Capital Essentials - White Paper

12 ways to faster wiring and harness design

Learn 12 ways in which Capital Essentials wiring and harness design solution can help reduce design cycle times, eliminate rework costs and improve margins.

TEL: +44 (0)845 644 0914

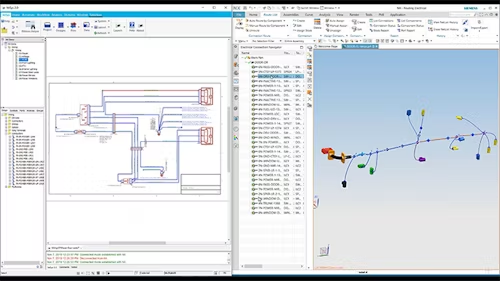

The progressively intricate nature of electrical design necessitates a revolution of the tools implemented by modern electrical engineers. Even straightforward contemporary products are often more complex than the pinnacle of 25 years ago. In order to manage these increasingly convoluted designs, engineers require electrical systems engineering software that simplifies the design task and facilitates efficient and expedient work. This document expounds upon 12 methods by which the Capital Essentials wiring and harness design solution can reduce design cycle times, eliminate rework costs, and enhance margins.

Efficient Design Cycle, Reduced Rework Costs, and Enhanced Profit Margins Result from Technological Advancements.

Capital Essentials is utilized by original equipment manufacturers (OEMs) and harness manufacturing companies globally, ranging from small, 10-person companies to large-scale industry leaders. With the incorporation of automation capabilities that eliminate labor-intensive and error-prone tasks, these companies have been able to reduce design-cycle times, minimize rework costs, and enhance profit margins. Some of the benefits offered by the system are:

- Advanced analysis and verification, enabling testing before construction, including MCAD integration

- Integration of a parts library to prevent errors in part selection

- Import of wiring directly from spreadsheets for quicker quotation turnaround time and design development

Download our whitepaper for an indepth look.

Learn More

ON DEMAND WEBINAR

Digitalizing the wire harness business

This webinar sheds light on the growing need for digitalization in the harness industry and how Siemens’ advanced harness design and manufacturing engineering solutions help companies transform challenges into competitive advantages.

WHITE PAPER

The power of automation and simulation for wire harness design

How can you manufacture increasingly complex wire harnesses in an efficient and accurate manner? Since harness design and manufacturing require seamless collaboration between various teams in various locations, continuing with traditional processes and solutions won’t cut it.

CASE STUDY

Reducing design error probability by 25 percent

Carraro Group uses Capital Essentials to reduce functional test time by 50 percent…